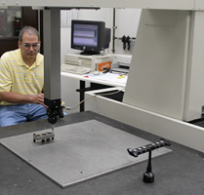

Using lean manufacturing, Zenith Cutter constantly evaluates processes, equipment and facilities to ensure we are producing the best products at the best prices. Our multi-step quality process ensures products are produced perfectly each and every time. With in-process inspections and a quality assurance program, there are steps all along the production line to verify products meet all specifications. In addition, our unique lot tracking system also monitors the progress from raw material to finished product.

And, because customers rely on us to consistently deliver products on time, we have established a stringent internal protocol to verify that you are never disappointed. Companies can count on Zenith Cutter to produce high-quality products and deliver them on time, every time.

Thorough Analysis for the Best Results

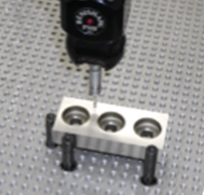

Zenith Cutter’s experienced Engineering and Research and Development staff work closely with our partners to optimize machine performance through joint development of the optimal cutting solution. Our deep roots in tool steel metallurgy, heat treat and coatings allow us to provide our partners with a competitive advantage.

And, as part of the Fisher Barton company, we benefit from its state-of-the-art Materials Lab which houses a full range of the most up-to-date instruments for the microscopic, chemical and mechanical analysis of metals and other materials. With these unique and comprehensive testing capabilities, better products can be created more easily and cost-effectively.